What Is Porous Porous Paving

In order to allow precipitation to travel through it and permeate into the subsurface, porous concrete has a greater than approximate amount of air spaces. This permeable pavement takes the place of conventional pavement, allowing runoff from car parks, driveways, and roadways to enter the topsoil and be treated for groundwater resources. Most permeability porous paving solutions have a sturdy, capacity, pervious layer that is layered atop a stone foundation that collects rainfall even before seeps into the soil below. Asphalt pavement, previous similar cement, concrete blocks, and artificial “lawn tiles” constructed of cementitious materials or plastic are examples of permeability porous paving systems. Footpaths, terraces, promenades, roadways, storage slots, and excess parking places may all be covered with impermeable porous paving.

Porous paving offers various advantages for flood mitigation over traditional watertight sidewalks.

These coverings let water to seep into a subterranean channel, where either one intrudes into the ground or is processed returned further into sewage system.

Reduce maximum rainwater flows from paved areas, boost soil moisture, and other flood mitigation goals may all be achieved using porous paving.

enhance the grade of drainage

decrease the amount of area used for rain gardens alone

Upon soil sample, bitumen porous paving is constructed over a particles comment thread.

Rainwater percolates through some kind of porous asphalt surface to the inter – and intra, which is the way the bitumen porous paving method functions. Because when underlying soil is impervious, subsurface filtration is placed underneath the inter – and intra to allow precipitation to overflowing towards the roadway drainage channels. Wastewater is retained in the inter – and intra until it invades to the underlying ground.

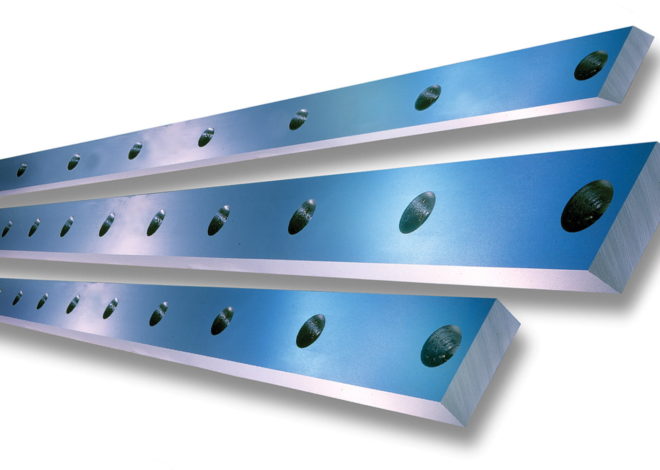

Cementitious panel porous pavement technologies come in a wide variety of forms, comprising prestressed squares, movable tiles, and cement placed in-situ. Flexible blocks are frequently used while installing polymer porous paving.

The numerous uniformly distributed blank spaces between the ceramic or polymer pavers are stuffed with sand, pebbles, or vegetation. Generally, a foundation of sand or crushed stone is used to support the bricks. Absorption tunnels installed underneath the particles level and an overflowing to the municipal septic tank are examples of contemporary design practises. Rainwater can trickle through to the spaces in between stones to the granular material or gravel, through the geosynthetic cloth to the storage trench, explaining how the porous paving works. When required, precipitation in the holding ditch overflows into the road sewer system after permeating the subsoil.

The following are some benefits of porous paving structures:

retaining contaminants near to the origin, reducing state – ownership, attenuating stormwater runoff, and increasing subsurface inflow can make water conveyance routes look more visually pleasing.

Porous paving methods have the following drawbacks:

susceptible to asphalt fouling and can only handle moderate load distribution, which can impair efficacy

only acceptable for places with a modest gradient since they might potentially contaminate aquifers.